Back to: Robotics & Artificial Intelligence (Class IX)

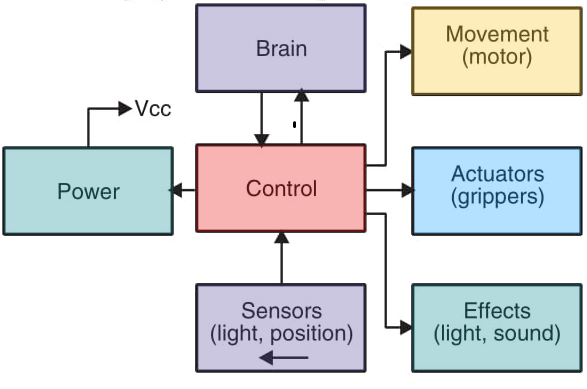

Robots are made up of several essential components that work together to perform tasks. These fundamental parts, or “building blocks,” are crucial for understanding how robots function. Let’s explore each of these building blocks:

Power Supply

- The power supply is the source of energy that powers the robot’s components. It could be a battery, a solar panel, or any other form of energy source. The choice of power supply affects the robot’s performance, runtime, and efficiency.

Sensors

- Sensors enable a robot to perceive its environment. They collect data from the surroundings, like temperature, light, sound, or obstacles. For example, a robot may use infrared sensors to detect objects or ultrasonic sensors to measure distance. The data collected is then processed to make decisions.

Actuators

- Actuators are devices that convert electrical energy into physical movement. They enable the robot to perform actions such as moving, picking up objects, or rotating. Common types of actuators include motors and servos. Actuators are like the muscles of a robot, allowing it to move or manipulate objects.

Controller

- The controller acts as the brain of the robot. It processes the data received from sensors and sends commands to actuators. The controller uses a program, often written in a language like Python or C++, to perform specific tasks. Microcontrollers like Arduino or Raspberry Pi are popular examples used in many robots.

End Effectors

- End effectors are the parts of the robot that interact with the environment. They could be tools like grippers, suction cups, or welding torches, depending on the robot’s application. For example, a robotic arm used in a factory may have a gripper to pick and place items.

Mechanical Structure

- The mechanical structure is the physical framework that holds all the components together. It determines the shape, size, and movement capabilities of the robot. The structure could be made of materials like metal, plastic, or composites and is designed to withstand the forces and loads experienced during operation.

Communication System

- The communication system allows the robot to communicate with other devices or systems, like computers or other robots. It can be wired (like USB or Ethernet) or wireless (like Wi-Fi or Bluetooth). Communication systems are crucial for coordinating tasks and exchanging data.

Controller

The controller is the brain of a robot, responsible for processing information, making decisions, and controlling the robot’s actions. It manages the flow of data between the robot’s sensors (input devices) and actuators (output devices), ensuring that the robot performs its tasks correctly and efficiently.

Key Functions of a Controller:

Data Processing:

- The controller receives data from various sensors, such as temperature, distance, or light sensors. It processes this data to understand the environment or the current state of the robot. For example, if a sensor detects an obstacle, the controller will decide how the robot should navigate around it.

Decision-Making:

- Based on the processed data, the controller makes decisions according to the programmed instructions. This decision-making process allows the robot to perform tasks autonomously, like moving in a particular direction, stopping, or picking up an object.

Command Execution:

- After making decisions, the controller sends commands to actuators (like motors or servos) to perform the required actions. For example, if the robot needs to turn left, the controller will instruct the appropriate motors to adjust their speed and direction.

Program Storage and Execution:

- The controller stores the robot’s programming code, which defines its behavior and tasks. This code is written in programming languages such as Python, C++, or Java. The controller reads and executes this code, enabling the robot to function as intended.

Communication:

- Controllers can communicate with other devices, such as computers, smartphones, or other robots. This communication can be done through wired connections (like USB or Ethernet) or wirelessly (using Wi-Fi, Bluetooth, or radio frequency).

Types of Controllers:

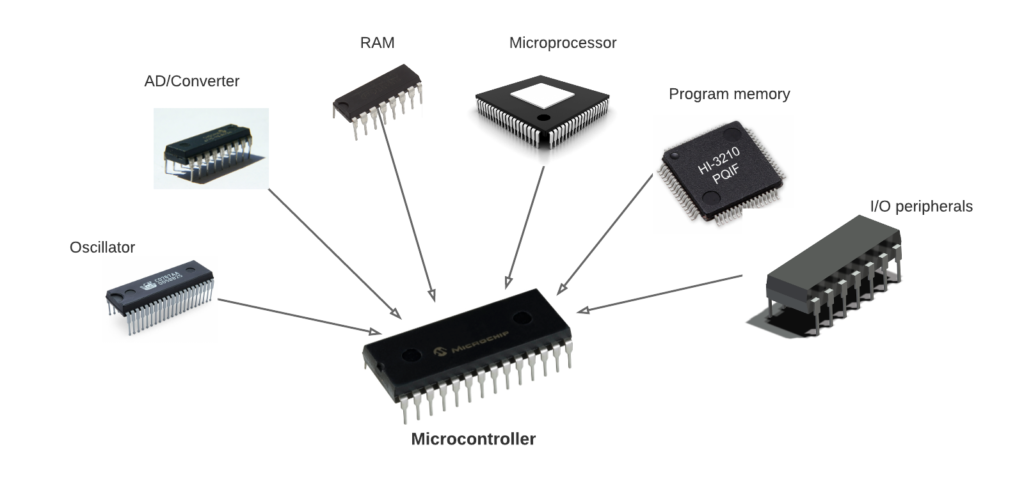

Microcontrollers:

- Microcontrollers are compact, low-power devices that integrate a processor, memory, and input/output (I/O) peripherals on a single chip. Examples include Arduino, ESP32, and micro. Microcontrollers are commonly used in simple robots due to their affordability and ease of programming.

Single-Board Computers (SBCs):

- Single-board computers like Raspberry Pi are more powerful than microcontrollers and can run complex programs, operating systems, and multiple tasks simultaneously. They are suitable for robots that require more computing power, such as those performing image processing or artificial intelligence tasks.

Programmable Logic Controllers (PLCs):

- PLCs are used in industrial robots and automation systems. They are designed for high reliability and control in harsh environments, such as manufacturing plants. PLCs are programmed in specific languages like ladder logic and are known for their robustness and ability to handle multiple inputs and outputs.

Identification of Robots

Industrial Robot

Humanoid Robot

Space Robot

Aerial Robot